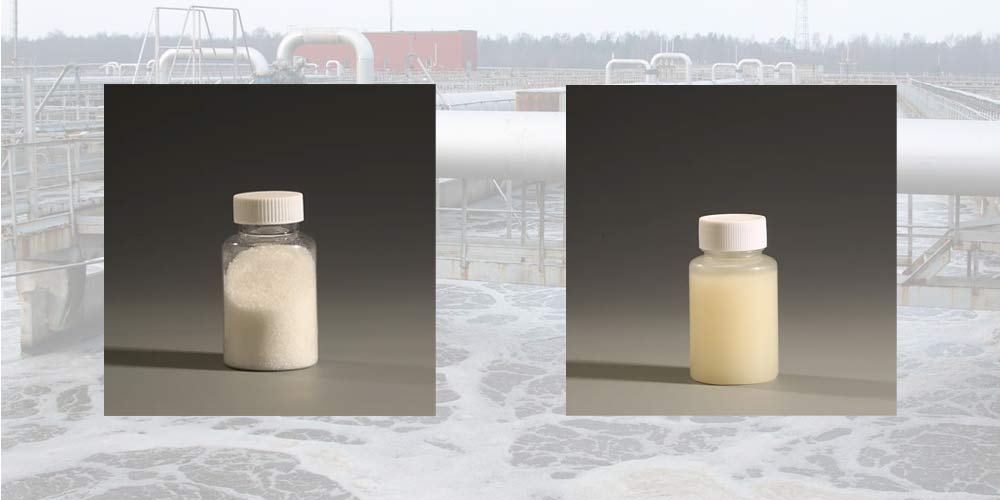

Polyakrylamid(PAM) jako důležité činidlo pro úpravu vody se široce používá v různých průmyslových oblastech. Rozpouštění PAM však může být pro mnoho uživatelů výzvou. Produkty PAM používané v průmyslových odpadních vodách se dodávají hlavně ve dvou formách: suchý prášek a emulze. Tento článek podrobně představí metodu rozpouštění obou druhů PAM, aby bylo zajištěno, že uživatelé dosáhnou nejlepších výsledků v reálném provozu.

Metoda přímého rozpouštění je nejjednodušší a nejběžnější metodou rozpouštění PAM. Tato metoda je vhodná pro prášek PAM s nižší molekulovou hmotností a snadno se rozpouští. Zde jsou konkrétní kroky:

Příprava nádoby: Vyberte čistou, suchou a odolnou plastovou nádobu, která je dostatečně velká, aby pojala potřebné množství prášku PAM a vody. Nepoužívejte kovové nádoby ani nádoby s kovovými skvrnami.

Přidání rozpouštědla: Přidejte příslušné množství vody.

Míchání: Spusťte míchadlo. Při míchání se ujistěte, že je míchadlo zcela ponořené v roztoku, aby se zabránilo vzniku bublin. Rychlost míchání by neměla být příliš vysoká, aby se zabránilo přerušení molekulárního řetězce PAM.

Přidání prášku PAM: Pomalu přidávejte požadované množství prášku PAM do nádoby za mírného míchání, aby se zabránilo poletujícímu prachu. Pokračujte v míchání roztoku, aby se prášek PAM rovnoměrně rozptýlil v rozpouštědle.

Počkejte na rozpuštění: Míchejte a sledujte rozpouštění prášku PAM. Obvykle je třeba míchat 1 až 2 hodiny, dokud se prášek PAM zcela nerozpustí.

Kontrola rozpustnosti: Po dokončení rozpouštění zkontrolujte průhlednost nebo index lomu roztoku, zda se zcela rozpustil. Pokud se objeví nerozpuštěné částice nebo shluky, pokračujte v míchání, dokud se roztok zcela nerozpustí. Pokud je molekulová hmotnost PAM příliš vysoká a rozpouštění je velmi pomalé, lze jej také vhodně zahřát, ale teplota by neměla překročit 60 °C.

Příprava nádoby a nářadí: Vyberte nádobu dostatečně velkou, aby bylo dostatek místa pro míchání. Mějte připravené míchadlo nebo míchací tyčinku, abyste zajistili důkladné promíchání roztoku.

Příprava roztoku: Současně přidejte vodu a emulzi PAM a současně spusťte míchadlo, aby se emulze a voda důkladně promíchaly.

Kontrola konečné koncentrace: Konečná koncentrace emulze PAM by měla být kontrolována na 1–5 %, aby se zajistil nejlepší flokulační účinek. Pokud potřebujete koncentraci upravit, pokračujte v přidávání vody nebo zvyšte množství emulze PAM.

Pokračujte v míchání: Po přidání emulze PAM pokračujte v míchání roztoku po dobu 15–25 minut. To pomůže molekulám PAM plně se dispergovat a rozpustit, což zajistí jejich rovnoměrné rozložení ve vodě.

Zabraňte nadměrnému míchání: Přestože správné míchání pomáhá rozpouštět PAM, nadměrné míchání může způsobit degradaci molekul PAM a snížit tak jeho flokulační účinek. Proto regulujte rychlost a dobu míchání.

Skladování a použití: Rozpuštěný roztok PAM skladujte na tmavém a suchém místě za předpokladu vhodné teploty. Vyhněte se přímému slunečnímu záření, aby nedošlo k degradaci PAM. Při použití zajistěte rovnoměrnost roztoku, aby se zabránilo ovlivnění flokulačního efektu v důsledku nerovnoměrného rozložení.

Čas zveřejnění: 22. srpna 2024